Who has the smaller ecological footprint: resins or osmosis systems?

Cleaning windows, PV and façades with pure water (pure H2O almost 100% pure water molecules, no minerals, no limescale, no other ingredients) is safe, economical and ecological. Fewer cherry pickers and ladders need to be used, the performance values are a factor of 3-4 compared to conventional cleaning, no chemicals are used and the surfaces tend to stay clean for longer. The water is usually provided and filtered using so-called mixed-bed resin systems (resins, DI filters, etc.) or real osmosis systems. Although the term "osmosis cleaning" has become established, the water does not always come from a genuine osmosis system.

Economic efficiency

From an economic point of view, pure water production with resins can only be used for small, occasional applications, as the running costs for the resin alone are around € 30-200 per 1000 liters of pure water. Where exactly you end up here usually depends on the resin system used and, more importantly, on the water hardness introduced.

Conventional osmosis systems generate running costs of around €1 per 1000 liters of pure water, regardless of the hardness of the incoming water, and are therefore often the better choice.

Waste water and environmental balance

Isn't that bad for the environment?

From an ecological point of view, RO systems also have a clear advantage when compared to resin systems, despite the susceptible "waste water" of 30%-50% of the input quantity.

Mode of operation

First of all, it is important to know that a mixed bed resin has a 100% yield. This means that we feed in 100 liters of city water and obtain 100 liters of pure water.

As the minerals are not "stored or collected" in a real osmosis system, but are "separated", the minerals are flushed out of the membrane with part of the city water fed in. This water is called "concentrate". It is not toxic or dangerous. It is simply twice as hard as the city water introduced.

The proportion of concentrate in simple, mobile osmosis systems is usually around 40-60%. More complex systems achieve a proportion of only 25-50% due to additional technology. Stationary systems or osmosis filling stations can also achieve 10-30% wastewater, whereby the membranes then also have to be replaced regularly, which is not the case with mobile RO systems.

Is waste water really a problem?

On the one hand, the susceptible wastewater is not "gone" and remains in the cycle as merely hard, but completely unpolluted or uncontaminated water and can be easily treated by the municipal waterworks - easier than any wastewater from a household, for example. It is important to understand that we are not talking about real water consumption here.

Resin systems and their ecological footprint

In addition, resin systems have a water yield of 100%. However, this is offset by a combined water footprint (gray and blue) of around 200 liters per kilogram of plastic produced (not to mention the other environmental impacts), which completely negates this advantage.

Although there are regenerated "reusable resins", these hardly have a better ecological balance, as they are blended with approx. 20% new resin and have approx. 20% less capacity than disposable resins. Finally, the reusable resin must also be transported to a processing plant after use. There, the resin is separated in an ultracentrifuge and "washed back" using chemicals. It is then blended and packaged before being sent back to the customer. Whether these points add up to a better eco-balance of "reusable resins" compared to "disposable resins" remains at least questionable.

Conclusion

All in all, however, it can be said that resin systems continue to be highly relevant in cleaning for small projects and occasional applications. We recommend the systems from Qleen, which you can find here: QLEEN PURASTART Mini.

However, regular use (especially in regions with medium or hard input water) means that osmosis systems are the more economically attractive choice.

From an ecological point of view, osmosis systems always are.

Tip

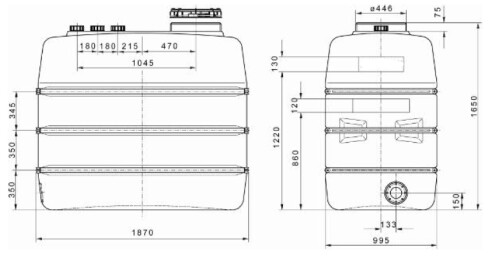

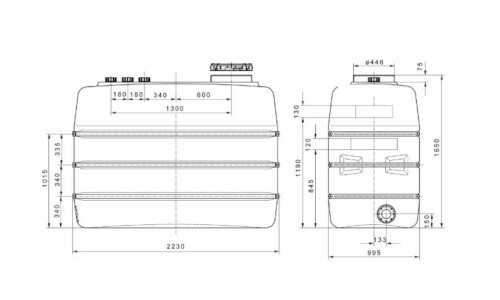

Osmosis systems with an even more economical X-Flow function or a built-in recycling valve can be found here: OSMOBIL PRO X or OSMOBIL MAX.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian