Solar cleaning: Everything you need to know!

The fact that PV and solar systems need to be cleaned is becoming more and more scientifically proven and generally accepted. Double-digit percentage increases in output can regularly be generated, especially on large and increasingly flat systems. More and more operators and owners want to clean their systems or even have to do so due to particularly high levels of dirt ingress. What needs to be considered here, what equipment is available, what performance values can be achieved with solar cleaning ? We provide the answers!

If you are in a particular hurry, you can go directly to the right category in our store here: Solar cleaning.

Overview and content on the topic of solar cleaning:

1. why and how often should solar cleaning be carried out? What are the benefits?

2. what is the basic principle for cleaning solar systems? How do I carry it out?

3. what water treatment systems are available for solar cleaning?

4 Which brush and cleaning systems are available for solar systems?

5 How much surface area can I clean per hour?

6. how do I deal with problem cases such as lichens and the like if I encounter them during solar cleaning?

7. can I use chemicals for solar cleaning and do I have to?

8. how often should solar cleaning take place and how can I calculate the loss of yield?

1. why and how often should solar cleaning be carried out? What are the benefits?

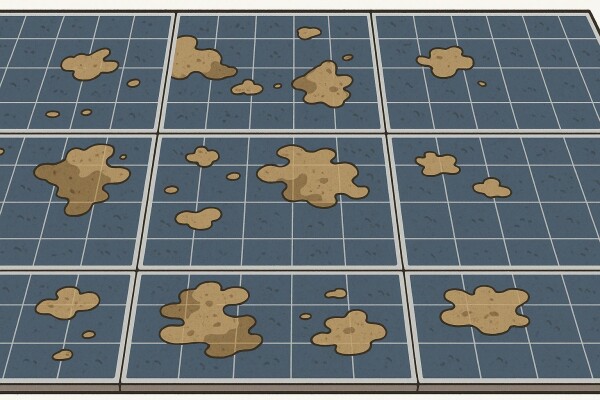

Solar systems (or PV systems) are constantly exposed to a wide variety of weather conditions and can lose efficiency due to dirt ingress and, put simply, no longer produce the amount of electricity that would be possible in a clean state. Solar systems that are built with a low inclination (i.e. quite flat) (e.g. less than 30° inclination) in particular tend to build up an adhesive dirt film quite quickly. This is also the case with steeper systems, but it happens less quickly and less strongly.

This firmly adhering film of dirt particles (which, incidentally, even rain cannot remove) ensures that the incoming light can no longer reach the panels or the cells under the glass shield as well, which means that less energy is converted into electricity than would be the case with a completely clean solar panel. However, there are also technical and substantial reasons for regular, proper solar cleaning. For example, pioneer plants such as lichen can actually penetrate the glass surface of the panels and contribute to hotspots and damage (and also reduce performance). We deal with the topic of "lichen" separately in this article .

The main arguments for solar cleaning are therefore summarized:

✅ Achieve optimum performance: Soiling can reduce efficiency by 5-30%.

✅ Prevention of hotspots: Accumulations of dirt can cause localized overheating, which can damage the solar modules.

✅ Achieve longer life expectancy: Regular cleaning can improve the durability of solar modules and keeps the surface of the modules intact.

✅ Better economic efficiency: A clean solar system generates more electricity and therefore increases economic efficiency.

What types of soiling occur on solar systems?

Atmospheric pollution, dust and pollen: Especially in agricultural areas or dry regions.

Lichens, leaves and moss: In areas close to forests or with high humidity.

Bird droppings: Can be particularly stubborn and shade parts of the module.

Industrial deposits: Soot, fine dust or chemical residues in urban and industrial areas.

Snow and ice: In winter, a thick layer of snow can completely prevent electricity production. Slipping" or defrosting occurs significantly faster on a clean surface than on a dirty one.

Other exotics: Brake dust from railroad tracks, tree resin, bitumen, deposits after fire damage, starch and grinding dust from agriculture

2 What is the basic principle for cleaning solar systems? How do I carry this out?

Basically, in normal solar cleaning, the surfaces are washed with washing brushes (bristles usually made of nylon) and pure water.

The question of the best medium or solvent for cleaning PV and solar systems follows the trend in glass and façade cleaning.

Pure water has various practical advantages here. The quality of this water is discussed separately in this article . For a whole range of reasons, this has become the industry standard for chemical-free cleaning over the last 20 years. Blasting processes (free HD applications, dry ice, sandblasting) are generally out of the question due to the protection of the substrate (HD and sandblasting) or high running costs and low surface performance (dry ice).

The use of effective cleaning chemicals, which offer a practical advantage, is generally out of the question for PV and solar installations, as it is usually impossible or at least uneconomical to collect the dirt.

In contrast to façade cleaning, there are simply no practical collection systems available or even inconceivable (e.g. simply impossible for large-scale and ground-mounted systems).

Pure water with a conductivity of 0-30 PPM offers very good cleaning performance, does not require collection or is not contaminated and ensures that surfaces dry without residue, which positively counteracts or delays new soiling. While the question of the medium or solvent ("pure water") is quite clearly regulated, there is a wide variety of options for the selected brushes or brush system, which are adapted to the respective design, contamination and size of the systems to be cleaned (rigid brushes, rotating brushes, robots, etc.). We offer various solutions and also complete sets that make it easy to get started!

3. which water treatment systems are available for solar cleaning?

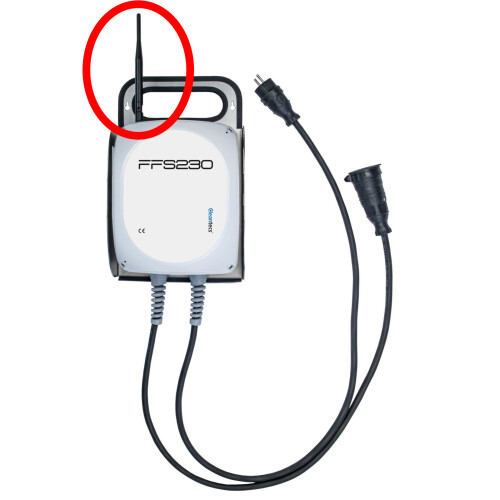

The principles of "mixed bed resin" or "osmosis technology" are basically used for the treatment of pure water in the field of solar cleaning, as all other processes are too expensive or unaffordable.

We have already dealt with the comparison of the two different systems in this article .

Basically, it can be said that real osmosis systems are generally used for solar cleaning, as these generate hardly any running costs, which is very important for water-intensive work such as solar cleaning. Only for the "self-cleaning" of smaller systems (e.g. up to max. 100 kWp up to a maximum of 1 cleaning per year), a mixed bed resin may be the right choice.

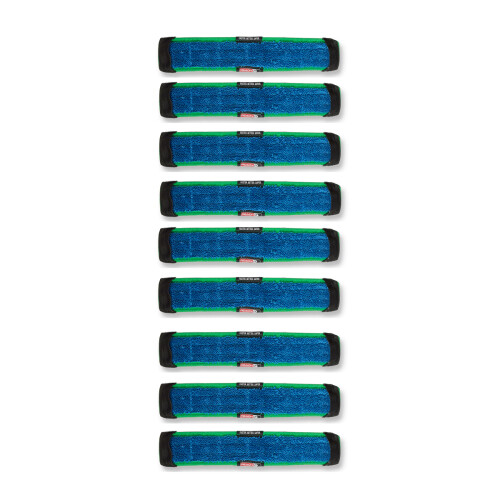

4. which brush and cleaning systems are available for solar installations?

For solar cleaning, we essentially distinguish between three categories of brushes and a special category of "blasting systems for lichen removal".

These are as follows:

- Rigid hand brushes: For small systems, less dirty systems or very steep systems.

- Rotating hand brushes: For medium and large systems and higher working speeds (e.g. up to 500 kWp).

- Solar robots: For large systems (above 500 kWp).

- Lichen remover: For basic cleaning of systems with moss and lichen infestation.

Of course, we also offer all of this as part of our popular"complete sets" if required.

5. how much area can I clean per hour with solar cleaning?

Basically, we can only start to ask the question of "area per hour" from a solar system size of approx. 50 kWp.

For smaller systems, the issue of "travel time, set-up time and organization" plays such an important role that we have to allow more time for this than for the actual cleaning.

For larger systems, the following has emerged based on 15 years of experience:

- Rigid hand brushes: 50-60 square meters per hour

- Rotating hand brushes: 120-160 square meters per hour

- Solar robots: 400 square meters per hour (small units) / 750 square meters per hour (large units)

- Lichen remover: 25-50 sqm (hand-held device) / 125 sqm (robot)

These are all practical "real" values that include set-up times, travel times etc. and are calculated from the perspective of a service provider.

All values are also based on normal contamination and do not include special cases (fire damage, tree resin, extreme ranges, floating systems, systems without water and electricity, etc.).

6. how do I deal with problem cases such as lichens and the like if I encounter them during solar cleaning?

As described above, we encounter exotic situations and problem cases in solar cleaning from time to time. The most common is certainly the issue of "lichen infestation".

Certified, safe and practical solutions based on vortex jet or rotary nozzles have been available for 2 years, which cut the lichen by means of a fixed angle of entry and a fixed distance between the jets, but do not damage the panel or the seals. The topic of "lichens" is dealt with separately in this article .

There is no patented standard solution for many other "problem cases". For example, solar installations next to railroad tracks may have residues of brake dust that simply cannot be cleaned professionally and are more likely to cause damage. Even after fire damage or if there are trees in the vicinity, "tree resins", for example, can cause damage rather than contamination that can be removed economically and efficiently, especially after a long exposure time.

In such special cases, we advise work samples and a disclaimer for the result and the surface to the customer. We can then work on a case-by-case basis and usually "textile-bound" or search for a solution. Here too, however, we often end up with a damage pattern or a cleaning process that exceeds the installation of new panels in terms of cost.

Accordingly, it is particularly important for service providers to recognize such cases in advance of cleaning and to differentiate themselves or even refrain from making an offer or accepting an order.

7. may I use chemicals for solar cleaning and do I even have to?

We have already dealt with this question in detail in the following article . Basically, the legal requirements in Germany are such that there are simply no effective and sensible products that can be used without catching the dirt. No matter how good and gentle the cleaning agents may be, this point is an exclusion criterion for the use of cleaning chemicals in solar cleaning, as collection is generally impossible or uneconomical and must also be carried out on roof systems (the products may not be used in roof drainage).

Although various cleaning agents are freely available for sale, the decisive statements can always be found in the safety data sheets (which is legally sufficient).

These not only state that the products must be collected and must not seep away, but also often enough that the products must not even be allowed to enter the sewage system after collection.

Accordingly, the use of chemicals in the service is generally out of the question and, apart from immense damage to the environment, it also carries a great liability risk, especially if the products are discharged into the environment as a commercial enterprise or company.

8 How often should solar cleaning take place and how can I calculate the loss of yield?

Basically, most solar systems need to be cleaned once a year. Especially for small, private PV systems with very steep roofs (over 30° inclination) and low environmental influences, cleaning may only take place after 3-5 years. The fact that "large" systems are very often flatter and also tend to be located in dirt-intensive areas (agriculture, highways, industrial areas) also speaks in favor of cleaning more often than once a year. Our PV loss calculator is a very useful tool for calculating when cleaning is advisable, not only from a material point of view but also from an economic point of view. You can find it here: PV loss calculator.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian