Photovoltaic cleaning and solar cleaning are tasks that have become increasingly important in recent years and serve to maintain or significantly improve the performance of renewable energy systems.

The price increases for electricity and energy in general, the increasing number of storage systems for self-use, electromobility and new vehicles that function as storage systems themselves, the energy transition and the slowly ageing (and dirtier) systems on the market have led to the need for cleaning most photovoltaic systems, which has been known to experts for many years, being understood more and more by system operators and companies. A new branch of services, cleaning technology and processes has emerged. We would like to provide an overview of this and address the following points:

- Do photovoltaic systems need to be cleaned?

- What performance gains can PV and solar cleaning bring?

- Which basic process is used?

- What water systems are available for cleaning PV and solar systems?

- What brush systems are available for PV and solar systems?

- How do I deal with special contaminants such as lichen, tree resin, bitumen etc.?

- When is a rotating brush worthwhile?

- When is it worth using a cleaning robot for PV systems?

- Can chemicals be used for PV cleaning?

First of all, however, we would like to give you the opportunity to go directly to the relevant categories in our store and store the latest and most innovative cleaning technology for PV systems directly from us when it comes to solar cleaning.

But now to our actual topic. Let's start with the following question:

1. do photovoltaic systems need to be cleaned?

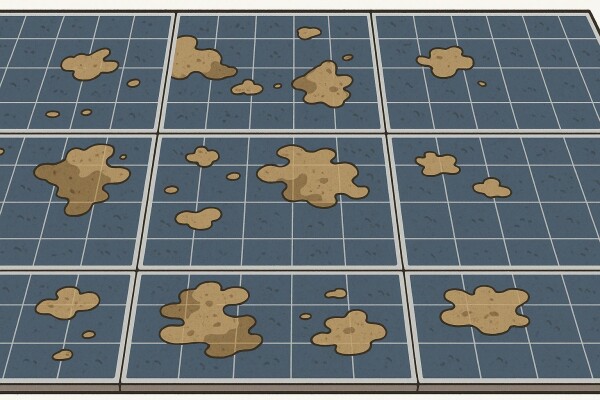

Basically, PV systems such as glass roofs and facades or almost all surfaces in the environment tend to accumulate atmospheric dirt, dust, green deposits and the like. These foreign particles then adhere to the surfaces to varying degrees and can form a film that looks unattractive, promotes further soiling and in some cases significantly restricts the performance of the PV system. In everyday life, this results in a need for cleaning on many systems, which, in addition to visual and substantial advantages, also pays off economically - but not on all of them!

The extent of this restriction in the performance of the modules is of course decisive for the question of when and whether cleaning the system is worthwhile. It is not really easy to measure these effects, as the weather is always very individual and the solar radiation itself changes. A kind of test setup is therefore always required in which the solar modules of one inverter are cleaned and those attached to another inverter are left "dirty" for an observation period if the actual effect of PV cleaning is to be measured.

In our many years of practical experience, we have seen performance increases of up to 30% as a result of cleaning, although anything above 20% is usually a special case (fire damage, bean dust, etc.).

The removal of normal soiling, which is not caused by exotic events, but by a normal soiling process, will usually result in a performance increase of 5-15%. The "self-cleaning effects", "nano-coatings" and similar promises sometimes made by module manufacturers do not usually last very long or are simply claims that cannot be fulfilled in practice.

Whether and to what extent or how quickly a PV system becomes dirty depends on various factors. These include

- Inclination of the PV system

- Ambient conditions or the installation location and height of the system

- Type of modules installed

- Age of the installed modules

- One-off special events

The most important influencing factor here is certainly the inclination of the PV system. A system with an inclination of 40%, for example, will always collect less dirt and grime than a system with an inclination of only 5% due to the rain, which can run off better and faster here. Here, gravity has less of an effect and therefore ensures that rain or snow with a lower flow rate also tends to remove and wash away less dirt.

The ambient conditions or the installation site are the second factor that has a significant influence on the intensity and speed with which a solar installation or PV system becomes dirty. A system that is located close to the ground near a rape field and a motorway has a much greater potential to pollute than a system that is installed in an industrial area on a 15-metre-high warehouse - even if both have the same inclination and design. If there is a sand-lime brick factory in the same industrial area, the situation may be different again. Other influences due to the installation location are, for example, unfavorable constellations due to shading and differences in humidity (e.g. in valley depressions etc.), forests or trees in the vicinity, floating systems (bird droppings and possibly salt), special industry in the vicinity (open-cast mining, mines, sawmills, railroad lines etc.).

The special thing is that the two main factors for the soiling of PV systems - the inclination of the system and possibly problematic environmental conditions - often come together on average in large PV systems (individual cases are of course always different) and together bring with them an immense potential for soiling. This in turn, with its large percentage reduction in performance (e.g. 15%), results in a very large loss in electricity production. With small systems, e.g. on private homes, it is often the exact opposite.

Examples are obvious: large systems are therefore often installed in agriculture and on fattening stables. Here we often have roof pitches of less than 20° and, in addition, an immense amount of dirt that is generated both by the fattening cattle (exhaust air systems or even open stable constructions) or by the surroundings (forests etc.). In most cases, such systems are also installed relatively close to the ground and not too high. Outdoor systems also often offer the combination of low inclination, installation close to the ground and a rather dirty environment. Small systems, on the other hand, are often installed on private homes. The sometimes immense roof pitches of usually 30° or more in combination with rather dirt-poor environments (e.g. residential areas) also ensure a rather low dirt load that is deposited on the modules. This results in a relatively small reduction in performance (e.g. 5%), which in the case of small PV systems only results in a very small reduction in electricity production.

Regardless of the inclination and environment, the quality of the modules, whether they are modules with or without frames and the age of the modules also play a role. Surfaces that have been exposed to wind and weather for 15 years, for example, tend to become porous and open-pored, while new surfaces are smoother and denser. Accordingly, mosses, dust, lichens and the like always find it easier to "dock" on old surfaces than on smooth and very new ones. However, both factors are rather negligible compared to "slope and environment".

Ultimately, incidents such as storms, fire damage, accidents or improper processes (e.g. grinding processes for grain and the like) can cause one-off and sometimes immense soiling, which must be considered on a very individual basis. Here and there, there are also cases where we no longer have to speak of contamination, but rather of damage.

2 What performance gains can PV and solar cleaning bring?

If you create a real test setup with a customer or for a field test (this requires PV systems with at least two inverters of the same design and orientation), performance increases of up to 30% can be observed, which are achieved by cleaning (we leave out exotic individual cases here, which may also have greater disadvantages and only consider "normal soiling"). Based on our experience, however, this is more likely to be 5-15% on average. Performance increases of more than 15% that can be achieved by cleaning are often associated with very long (too long) cleaning intervals. Annual cleaning generally results in performance gains that do not exceed 15%. The following applies: the flatter and larger the system, the more likely it is that cleaning will pay off. The steeper and smaller the system, the more visual aspects are in the foreground and less economic advantages are achieved by cleaning.

3 Which basic process is used?

Basically, the work of "PV cleaning" falls into the large field of cleaning work, which is often summarized under the keyword"osmosis cleaning" and thus uses a certain water as a solvent or cleaning liquor and usually also washing brushes, telescopic rods, rotating brushes or even robots, which are fed with the corresponding water.

The basic aim is to work without chemicals and as gently as possible. Both are essential. Work must be chemical-free, as collecting the dirt is usually impossible or at least not affordable. This is where the method that has been established for decades in glass and façade cleaning comes in, in which pure water (99% pure H2O molecules) is used as the only liquid medium to dissolve and remove dirt. The pure water is produced with mixed bed resins or osmosis systems, whereby osmosis systems are primarily used in the field of PV cleaning. Mixed-bed resins are ruled out here due to the sometimes large quantities of water required, as they generate excessive running costs.

Careful work must be carried out at least in the service (but also in in-house cleaning) in order not to damage the often expensive assets and investments in the future and to only clean them, but not to change them.

Pure water offers various practical advantages here, which we will come to in more detail in a moment. However, it is also important that we use a medium with which PV systems come into contact anyway: Rainwater, as long as it is in the air, has the same composition as the pure water that is obtained with systems such as the Unger Hydropower(mixed bed resin) or the OSMOBIL PRO X(osmosis system). Accordingly, it is already clear that this water is absolutely unproblematic for PV systems.

For owners of small systems, it may therefore also make sense to simply buy a washing brush and wash the surfaces in heavy rain (simple, normal rain is not sufficient). For service providers and owners of large PV systems, this is of course out of the question. As a rule (not necessary in soft water regions with less than 3° DH), an osmosis system or mixed bed resin must be purchased for sustainable and professional cleaning.

The collection and subsequent use of rainwater is also possible, but is associated with various question marks and problems, which we will explain elsewhere.

Here we offer a shortcut to our mobile osmosis systems for building cleaning.

So what are the practical advantages of pure water for cleaning? The same arguments apply here as for glass and façade cleaning:

- Basically, surfaces that have been properly washed off can be left wet and do not need to be hauled off. The remaining water on the modules evaporates 100%.

- The surfaces are then stain-free. As no lime, soap or surfactant residues remain, it is extremely difficult for new dirt to adhere to the relatively smooth surfaces of the panels.

- The use of pure water makes techniques such as rotating washing brushes, telescopic poles, cable guides or robots possible, resulting in high performance values per hour and low costs for lifting platforms, scaffolding and the like.

- The water is active in cleaning and attempts to recover the minerals previously removed. This effect ensures that the dissolving properties of the water are improved and the surface tension is massively reduced. Both dissolve dirt and sponge it up - much better than a normal or even hard and mineral-rich water could.

- As there is no chemical-laden dirt liquor, there is no need to collect, drain or even treat the dirt liquor.

- No conflicts with damage or panel manufacturers to be expected. The modules are already in contact with chemically identical water when it rains.

4 What water systems are available for cleaning PV and solar systems?

As with the cleaning of windows and facades, two basic principles can be considered for the production of pure water for PV cleaning. These are essentially Mixed bed resins or osmosis systems (we deliberately do not go into exotic mixed bed forms and other processes here, as these are practically irrelevant).

In simple terms, mixed bed resins - you can find a selection of our products here - are simple granulate filters that bind all minerals and molecules except the desired H20 molecule. The tap water flows through a bottle or pressurized container and is filtered as it flows through. As soon as the resin is saturated and can no longer bind minerals, it must be replaced and disposed of or regenerated. The systems are robust, often do not require electricity and all water sources can be used.

In most cases, the purchase price of €350 is also quite reasonable.

However, the main problem here is the running costs. Depending on the selected system and the local water hardness (which has an extreme influence on the range of the resins), the net costs are between €50 and €200 per 1000 liters of filtered pure water. This aspect must be taken into account and often ensures that the use of mixed bed resins is not worthwhile for regular work or large projects (even if these only occur once a year for in-house cleaning). The relatively short ranges (no increase in pressure), low liter output per hour (water must not flow through the resin too quickly) and the handling of the bottles and resin exchange (sometimes very complex and time-consuming) can also be arguments against mixed bed resins. However, if you want to clean a small system (e.g. 50 kwp) 1-2 times a year, you can do this quite well with a mixed-bed resin, even in regions with hard inlet water.

Osmosis systems (chem. correct actually reverse osmosis systems) - click here for the products - also produce pure H2O. Put simply, this is done using a sieving process: The tap water is forced through a membrane at high pressure, which only allows the H2O molecule to pass through. Fortunately, this is the smallest particle that occurs in water. The 100 liters of tap water that enter the system are turned into approx. 50 liters of pure water and 50 liters of waste water, which carries the minerals that build up in front of the membrane out of the device. As the membranes show no wear, with the exception of misuse due to well water and frost or bearing damage, this process can be carried out with almost no running costs. Depending on the system, however, there are different pre-filters and after-filters that need to be replaced. High-pressure osmosis systems (such as the OSMOBIL PRO X) have running costs of less than €1 per 1000 liters of pure water. Even low-pressure systems (with multi-stage pre- and after-filters) have running costs of only € 2-3 per 1000 liters, which is still far below the running costs of a mixed bed resin. Even the slightly higher water consumption of an osmosis system (part of which cannot be used for cleaning) does not offset the often immense advantage of the osmosis system in terms of running costs.

The decisive factor, however, is that an osmosis system must also be used for a corresponding number of operating hours or days per year for the purchase to be worthwhile. After all, the purchase price for osmosis systems is €3000 net and upwards. It should also be noted that osmosis systems always require a 230 volt connection (sometimes even 400 volts). In return, in addition to low running costs, you also get more water per hour and a greater range from the water filter to the work site than with a mixed bed resin.

5 What brush systems are available for PV and solar systems?

The fact that pure water is the agent of choice for the right transport and solvent when it comes to cleaning PV systems has been discussed in detail above.

discussed in detail above. The industry also agrees on this and there is a very clear industry standard.

The question of which brush and bristles are used and whether they are fixed, rotating or even moving brushes is much more complex and has more options.

Click here to see the products and complete sets for PV and solar cleaning that we offer: This way.

Basically, all brushes and bristles that we offer here are approved or certified for cleaning PV systems and come from reputable manufacturers. As always in cleaning, however, the same applies here: This does not always protect against scratches! The softest brush in the world may cause scratches if it is not properly maintained, cleaned or used correctly. Apart from this, our bristles from manufacturers such as GARDINER, UNGER, Cleantecs, hyCLEANER, REACHit, Lehmann and others do not scratch PV systems.

The question of "fixed brushes", "rotating brushes", "moving brushes or even robots", as described at the beginning, is an interesting one. When does it make sense to assume that "clean water and a brush" is the method of choice when it comes to PV cleaning?

Basically, this is relatively simple:

"Rigid brushes for PV cleaning":

Rigid brushes are usually found on small PV systems and are usually run on carbon or fiberglass poles with water guides. They are inexpensive, require very little water and offer an immense reach when guided on a pole, with low weight. With high-quality carbon poles, this can be up to 20 meters depending on the slope and other conditions! As a rule, they are no less effective at removing dirt than other systems. Rigid brushes on the respective pole can often be extended on the ground and placed on the roof or PV system with a reach of 6-8 meters.

This is strenuous due to the leverage, but it works! PV systems with an appropriate inclination can often be cleaned from the ground without the need for cherry pickers, ladders and the like, even if the system only starts a few meters above the gutter. This is not possible with any other system! Rigid brushes also offer immense advantages when PV systems are installed on very steep roofs. There, the user has to "carry and control" a large part of the weight of the brush and pole, as there is less weight on the panel than with a rather flat design (where it often "feels" like the entire weight is on the panel and the pole and brush only have to be guided).

However, as people do all the work when using rigid brushes and also have to guide the Pole and brush at the same time, this technology reaches its limits when the systems become larger. For systems of 50 KWP or more, we recommend considering a rotating brush.

However, whether these really make more sense and are "faster" must be assessed on a case-by-case basis (see "Inclination" above).

Performance values in terms of "square meters per hour" are usually in the double-digit range between 25-75 m² per hour for manual cleaning with rigid brushes.

"Rotating brushes for PV cleaning":

From a system size of 50 KWP, rotating brushes often make sense, especially if this type of work has to be carried out more frequently.

These systems are more expensive and require more water per hour. Nevertheless, the physical strain on the cleaning personnel is significantly less (unless the delivery is too large or the incline too steep), while the performance values are in the low, three-digit range and up to 250 square meters of PV and solar system can be cleaned at the same time under optimum conditions.

The established systems on the market generally rely on a hydraulic water drive, which is operated by a small high-pressure pump. Cleantecs is the market leader here and the SOLA-TECS C systems are standard.

Directly behind these are the electric systems from Lehmann, which also offer some practical advantages and consume less water. All in all, the larger the area to be cleaned per year, the more we recommend using rotating brushes driven by water pressure, while small systems or service providers who want to clean PV from time to time can certainly use the electrically driven ROTAQLEEN systems, which can also be used vertically (i.e. for glass cleaning) due to their lower weight.

"Self-propelled brushes for PV cleaning":

By self-propelled brushes, we do not yet mean robots (these will come later), but first of all the special solution from Cleanctes called SOLA-TECS W. Here, the brush is lowered from the ridge on a supply line (high-pressure hose). The brush rotates and moves downwards by gravity and is then retrieved by the user. This is a very special form of application that can only be used under certain conditions (I have to be able to work from the ridge, after all - the issue of "work safety").

However, if I can work from the ridge, the SOLA-TECS W can be used to achieve immense ranges (up to 30 meters) and even greater output values. These can be up to 350 square meters per hour. However, it should be noted that the SOLA-TECS W also requires 600 liters of pure water per hour, which places great demands on the water tap and the osmosis system (mixed bed resins are no longer an option here), but these can be solved with our products and our advice.

As a rule, this product makes sense for customers who want to clean their own large systems and have the appropriate conditions to be able to work safely "from the ridge". Service providers also use this product, but rarely.

Anyone who is regularly confronted with cleaning PV systems that are 200 KWP and larger must look into purchasing a cleaning robot in order to continue working economically. Although these cleaning machines also have a few preconditions that must be met (inclination of less than 25°, flat structure, access to the roof), they can also cover 4-digit square meters per hour, which can go up to 2400 square meters per hour with the solarROBOT pro from hyCLEANER. The systems consume 400-800 liters of clean water per hour, but achieve the best ratio of "water per cleaning area".

6 How do I deal with special soiling such as lichen, tree resin, bitumen etc.?

Basically, normal cleaning of PV systems with brushes and pure water can remove certain contaminants and not others.

Atmospheric soiling, green deposits, bird droppings (if not too old) etc. can usually be removed easily and without leaving any residue.

One classic that we are encountering more and more frequently and that is usually impossible to remove is lichen.

Special tools are used here, such as the lichen remover from Cleantecs, which we cover in a separate report and link to here.

Other contaminants that we tend to classify as "damage" can include tree resin or bitumen.

Fire damage, accidents or other exotic substances can also be deposited on PV systems that adhere firmly and can no longer be removed as part of a quality-assured cleaning according to the state of the art and in accordance with the specifications of the module manufacturer and therefore represent damage that cannot be healed by the "cleaning" service without damaging the surface, for example. Whether special solutions can be found here after approval by the customer (solvents, blades, pads, possibly the use of chemicals, etc.) must be critically evaluated and checked on a case-by-case basis. In practice, a similar distinction should be made here as is made for the "glass cleaning" service. There, a distinction is also made between normal cleaning and basic or intensive cleaning or even just a "cleaning test".

7 When is a rotating brush worthwhile?

Even though there are, of course, numerous exceptions and PV cleaning involves very different types of construction, ranges, inclinations, soiling, etc., it can be said that a rotating brush is often worthwhile when PV systems are 50 kwp or larger.

8 When is a cleaning robot for PV systems worthwhile?

We advise customers to purchase a robot if they regularly have to clean PV systems that are 200 KWP or larger.

Owners of systems who want to carry out their own cleaning can also consider purchasing a robot from approx. 500 KWP if cleaning is to be carried out at least twice a year.

9. may chemicals be used for PV cleaning?

There are now a number of cleaning products (chemicals, additives, etc.) that are formally approved for use on PV systems (but cannot or must not be used in practice), but whose manufacturers generally do not address a fundamental problem or leave it to the user (more on this later).

A brief digression: I would also like to emphasize that our focus is on chemical-free cleaning. However, we are not "chemical opponents" and, as cleaning experts, we know very well that there are applications where pure water is not enough.

We can think of a whole range of other products that could achieve good effects on the surfaces of PV and solar systems and would help with real problems (resin, bitumen, etc.).

However, when it comes to PV and solar cleaning, people tend to overlook the fact that we, as tradespeople, are obliged to collect the dirt that accumulates, discharge it into the sewage system or even treat it and dispose of it separately. What many users do not know: The statement or property "biodegradable", which can sometimes be found on products, makes no statement as to whether a product may simply be discharged into the environment or seep into the ground (open-air system) or be introduced into the roof drainage system. It merely represents a kind of "half-life". We are not aware of any product that works and is also legally permitted to seep into the ground (at least in Germany). We want to emphasize this very clearly. We are monitoring the market and will be happy to revise our opinion in due course. When and whether this will happen cannot be predicted at present.

Until then, it is important to collect and drain off the available cleaning agents and their dirt after cleaning!

This may be possible here and there with roof systems. However, the effort involved in regular, normal PV cleaning (where clean water and brushes are sufficient) is disproportionate. In the case of ground-mounted or even floating systems, it currently seems technically impossible or completely uneconomical to collect the dirty water, which is why we believe that the use of cleaning chemicals and additives on PV and solar systems is currently out of the question.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian