Rotating brushes are often considered when large glass and façade surfaces or PV systems need to be cleaned. We explain what models are available and when they make sense!

An overview:

- Why are rotating brushes offered and what are they intended for?

- What technical implementations are there?

- What models and products are available?

- Rotating systems on PV and solar

- Rotating systems on glass surfaces

- Rotating systems on facades

- Rotating systems on slats and solar shading

If you would like an insight into our product world beforehand, click here.

Why are rotating brushes offered and what are they for?

In times of an excessive shortage of skilled workers, an ever-increasing importance of work ergonomics and sick leave and, last but not least, more and more PV and solar systems, rotating brushes are becoming increasingly important in glass, building, PV, façade and slat cleaning.

With rotating brushes, the traditional "scrubbing motion" performed by humans on a surface during cleaning is outsourced to a motor or gearbox and the energy otherwise used by humans ultimately comes largely from the socket in all systems. This significantly and noticeably reduces the physical workload for workers.

Furthermore, most rotating cleaning and brushing systems not only reduce the workload but also achieve significantly higher area coverage per hour than manual brushes, pads, etc. This is therefore clearly an economic aspect and at the same time an answer to the issue of a general shortage of manpower.

Ultimately, rotating brush systems always lead to a better and more uniform cleaning effect.

This is due to the significantly higher "uniformity" and the greater mechanics that the systems bring to the respective surface during cleaning. While manual cleaning inevitably involves large deviations in terms of contact pressure and scrubbing frequency, and the progressive fatigue of the employee also has an influence, these factors are not completely standardized with rotating systems, but they are standardized as far as possible. In addition, the high rotational speeds of the systems mean that the surfaces are processed much more intensively and frequently with the respective bristles than would ever be possible with a fixed brush head and manual work (despite the higher working speed).

What are the technical implementations?

Most rotating cleaning systems for solar, PV, glass, façades and slats are driven by an electric motor. This is a tried and tested system that generally uses 12 or 24 volt motors, which are supplied by a transformer via the mains or, if necessary, via a built-in battery. The systems are generally very durable and offer good to very good cleaning results. There is no alternative to this principle, especially for solar robots.

Electric motors are also frequently used for cleaning slats, glass surfaces and PV systems with rotating roller brushes. This is the case, for example, with the systems from ROTAQLEEN or the AJR from SPS.

The hyCLEANER robots also rely on electrically driven brushes. The clean water previously treated by osmosis (mixed-bed resins are usually not economically viable due to the high water volumes with rotating brushes) is then usually sprayed over the brushes and distributed very quickly in the cleaning area. In general, it can be said that electrically operated rotating brushes have a moderate water consumption and generally have a very good cleaning effect.

When working on telescopic poles in particular, the power cable, which is of course essential, is often seen as a problem as it has to be connected to the pole alongside the water supply and is usually located on the outside. However, it is easy to learn how to use it.

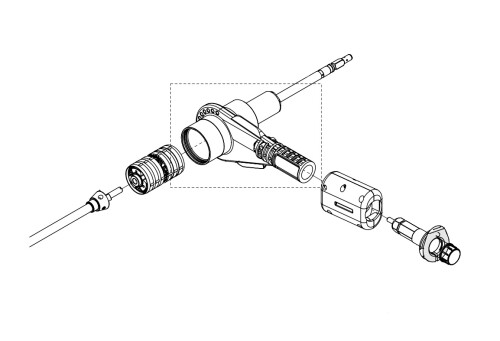

However, there is a completely different approach with Cleantecs products, especially for solar and slat cleaning: here the brushes are driven by a hydraulic water gearbox. The clean water is "accelerated" with a high-pressure cleaner and the devices always have a high-pressure hose as the connection or supply line - but only a hose and no power cable.

The 100-120 bar from the high-pressure cleaner is sufficient for the drive and also generates higher rotational speeds than most electrically driven brushes.

In addition, this results in a very slimline setup, especially when working on telescopic poles (SOLATECS C), as an internal high-pressure hose can be used with some poles (e.g. GARDINER) and no cable has to be routed outside.

The same applies to slat cleaning. Here, too, the electric models inevitably have a power cable and a water hose for the supply, whereas the water-powered model only needs a water pipe. However, this disadvantage is negligible in this case.

What models and products are available?

We offer the following products in the field of rotating brushes for PV and solar:

- SOLA-TECS C and W from Cleantecs

- ROTAQLEEN Classic and Vario from QLEEN

- solarROBOT compact and pro from hyCLEANER

We offer the following products in the field of rotating brushes for solar shading slats:

The following rotating brushes can also be used for vertical glass surfaces and facades:

- ROTAQLEEN Classic

- SOLA-TECS C

Rotating systems on PV and solar

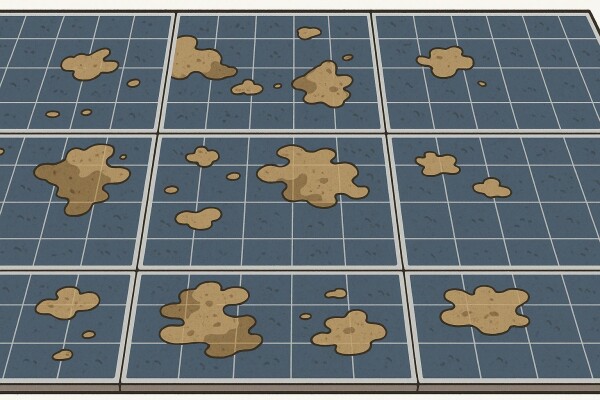

Rotating brushes are most important on solar surfaces and PV systems. This will not change in the coming years and decades in view of the expansion of these systems that lies ahead. PV systems (we would say from approx. 30 KWP) quickly become so large and sometimes very dirty that manual cleaning is hardly reasonable and is not always successful.

As the size of the PV systems increases, so does the principle of the rotating brush that is used. While smaller systems are usually processed with devices such as the SOLA-TECS C or the ROTAQLEEN, the regular cleaning of systems from 100 KWP upwards reaches its limits (this is and remains physical work). Of course, a SOLA-TECS C, for example, can also be used to clean PV systems with 500 or more KWP. However, this quickly becomes uneconomical and should be reconsidered, especially if this occurs frequently. Robots such as the hyCLEANER devices are often the right choice. This allows the performance values or area performance per hour to be increased even further. Basically, however, the topic is and remains very individual, as the inclination, display, cleaning frequency, etc. have a major influence on the question of which system is most efficient and best suited for cleaning.

Rotating systems on glass surfaces

A basic distinction must first be made here between "vertical", i.e. normal glass surfaces and glass roofs, which are often very horizontal or have only a slight incline.

We encounter the cleaning of vertical glass surfaces extremely frequently in everyday life. As the weight of the rotating brush, which for technical reasons is always many times greater than that of manual brushes, is almost entirely on the Pole and thus on the user and generates extreme leverage at the end of the Pole, rotating systems are rarely used here and are generally not really useful. At best, the ROTAQLEEN Classic for glass can be recommended as a system here and can be used effectively up to a height of approx. 12 meters. However, as we often have to deal with non-contiguous surfaces and other soiling on PV glass, this is often not necessary or not really efficient.

The situation is different with glass roofs. Almost all the systems mentioned above can be used well here.

Here too, the same assessment applies to the question of which system performs best on which overall surface to be cleaned.

Rotating systems on facades

Many of the restrictive arguments against the use of rotating brushes on (vertical) glass (see above) also apply to facades.

Cleaning with a rotating brush can be particularly useful for chalking, powder-coated facades and can produce a great polishing effect. In this case, the work should generally be carried out from a cherry picker and with a SOLA-TECS C and a very short Pole. In some cases, it can even be efficient for one employee to "control" the brush and another to operate the riser.

Overall, the use of rotating brushes on facades is negligible.

On large surfaces, however, the facadeBRUSH from our partner hyCLEANER is highly recommended!

We do not offer these in the store, but you can request them directly from the manufacturer here!

Rotating slat and sun shading systems

The number of popular and modern sun shading systems made of slats is constantly increasing.

Accordingly, manual brushes or the rigid slat cleaner from QLEEN are no longer sufficient for large areas and regular cleaning. In addition, the mechanics of manual systems are often not sufficient to remove dirt from the slats if they have not been cleaned for several years. This is where the use of rotating systems such as the GTR from CLEANTECS or the AJR from SPS quickly pays off for economic reasons (working speed), ergonomic reasons (strain on the employee) and with a view to the cleaning result (higher mechanics).

The cleaning speed (which then also reaches the tension and ladder belts and the underside of the slats) is 5-10 square meters per hour, whereby one-sided subsequent cleaning of the windows from the outside is already included. Unfortunately, these systems cannot be used on telescopic poles due to the high dead weight and the need to thread very delicately between the slats. Accordingly, the second floor must be worked on with rolling scaffolding or a cherry picker.

Ladders are often out of the question (even below the permissible 5 meter limit) as they cannot be leaned against the closed slat system.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian