We would like to answer this question, which we are often asked in connection with cleaning work on glass surfaces, windows, façades and PV systems, in detail today. In order to answer the question "Glass cleaning with osmosis - what is it?" correctly, we will go into the following points:

- What is osmosis water?

- Is osmosis water useful for glass cleaning?

- Does the water really dry without leaving any residue?

- Osmosis cleaning for building cleaners - which systems?

- What else can I use osmosis water for cleaning?

What is osmosis water?

First of all, osmosis water is a colloquial term for water that consists only (or almost 100%) of water molecules and that has usually been produced or filtered with a real osmosis system (or with a mixed bed resin). Related or synonymous terms that you will come across in cleaning work, but also in industry or chemical processes and which all mean the same thing are Pure water, process water, ultrapure water, product water, permeate, ultrapure water, demineralized water, deionized water, distilled water, demineralized water etc..

The liquid that we call "water" in everyday life and that comes out of our taps, for example, consists of far more than just "real" water molecules (H2O) and is therefore very different from the osmosis water mentioned at the beginning. In addition to numerous microorganisms and dissolved minerals and substances such as iron or manganese, untreated tap water usually also contains many calcium and magnesium molecules. In combination, we know the two under the collective term "lime". Together they make up the so-called carbonate hardness of the water (part of the total hardness). It is precisely these two "colleagues" that we primarily do not want to have on the cleaned surfaces when cleaning after drying - i.e. after the H2O molecules have evaporated. They would leave unsightly stains and also massively promote new soiling of the surfaces. In addition, dissolved in the water, they prevent the actually great, cleaning-active properties of pure water or osmosis water, which are created by the fact that the water urgently wants to "get back" the previously removed minerals and therefore sponges up dirt and organic substances "in search of minerals" and sets them in motion.

To determine whether a water is osmosis water or pure water, it is advisable to determine the so-called conductance of the water. The conductance, which we measure in PPM or microsiemens, indicates how well electricity can be conducted through the water. The fewer foreign particles there are in the water, the worse the water conducts electricity. Incidentally, absolutely pure H20 does not conduct electricity at all.

The unit of measurement "PPM" has become established for cleaning work. This stands for "Part Per Million" and indicates the actual number of foreign molecules that can be found per 1,000,000 H2O molecules in the water. Our tap water in Germany has conductance values of between approx. 100-520 PPM - i.e. 100-500 foreign bodies per 1,000,000 H2O molecules. We speak of pure water or osmosis water when a purity of less than 30 PPM is achieved. This is suitable for solar and façade cleaning. For cleaning windows or transparent surfaces, we even need a degree of purity of less than 15 PPM. Incidentally, 1 degree of German hardness (1° DH) corresponds to 17.8 PPM. Accordingly, a hardness of "below 1°DH" is required for glass cleaning and approx. "below 2°DH" for solar cleaning.

Does osmosis water make sense for glass cleaning?

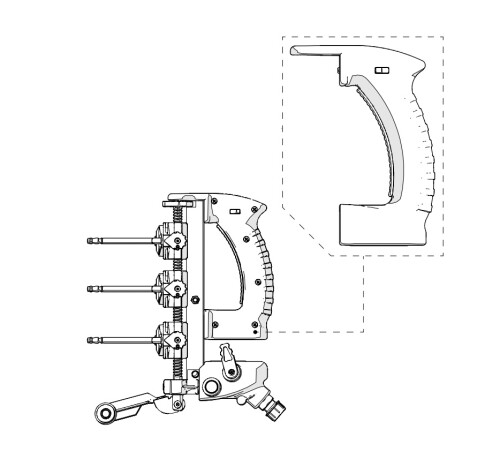

Osmosis water has the property that it evaporates almost 100%. The previously washed surfaces can therefore simply be "left wet". In addition to other positive properties, this is the key to being able to clean windows from the ground with carbon poles at heights of up to 25 meters. This makes it possible to dispense with expensive cherry pickers, avoid complex and dangerous ladder and scaffolding work, reduce the use of chemicals (no need to collect the dirt), increase the intervals between cleaning and re-soiling and at the same time drastically increase the working speed compared to classic glass cleaning. After all, a washing brush can be guided over the surface to be cleaned accurately and comprehensively up to extreme heights. Subsequent "stripping" of the surfaces, as would be necessary when using soaps, surfactants or calcareous tap water, is only possible at a height of 4-5 meters. Anyone familiar with classic glass cleaning knows very well how difficult this is when it comes to achieving a streak-free and flawless result.

Another extremely positive property of osmosis water is its active cleaning effect. This is due to the fact that the water or the remaining H2O molecules "want the previously removed minerals back" under all circumstances. Put simply, there are free, charged "docking sites for minerals" on the molecules that need to be occupied. This property generates a cleaning activity and sponges up the dirt and sets it in motion, similar to the processes that occur when surfactants and soaps are used. Pure water or osmosis water can do this much better than untreated tap water.

Here are the advantages of glass cleaning with osmosis water at a glance:

- Cleaning from the ground at a height of up to 25 meters

- often no lifting costs

- with significantly higher working speed

- and significantly improved work safety

- and significantly less use of chemicals

- and noticeably delayed resoiling of the surfaces

- and no need to collect the dirt

- Can also be used on facades, PV systems and solar panels

Does the water really dry up without leaving any residue?

Answering this question in a blog post is of course quite simple: Yes, pure water with a conductivity of less than 15 PPM dries without leaving any residue. If you can't formally believe this, here are a few thoughts on the subject, which will ultimately allow you to carry out a simple experiment. Of course, we also invite everyone to test this or simply come to our exhibition.

To the experiment:

If you don't have an osmosis system or mixed-bed resin and don't want to come to us, you can start by tipping a small bottle of tap water onto a pane of glass and letting it dry. The result is stains consisting of all the molecules in the water that are not H2O particles. The H2O evaporates completely. After all, depending on the temperature and humidity in the room, the pane will be dry after a few hours at the latest - right? If you now imagine that you let water dry up that consists only of H2O molecules, it may be easier to imagine the effect without visual material. If you still have doubts, you can buy a bottle of distilled water in the supermarket. This water expressly does not have the purity of water obtained with an osmosis system or a mixed bed resin. As a rule, distilled water is only 15-30 PPM (distillation is another method of demineralizing water). Nevertheless, hardly anything will be visible if a small bottle of distilled water is tipped out onto the same disk instead of tap water and the H2O has evaporated later.

The fact that this technique has become the industry standard in glass, façade and PV cleaning over the last 20 years and that you rarely see glass cleaners standing in a cherry picker is a further indication that the "osmosis cleaning" approach works.

Osmosis cleaning for building cleaners - which systems?

While there are other ways of obtaining pure water (or osmosis water) in industry or for chemical and medical applications, there are only sensible and reasonably economical options for cleaning projects: Osmosis systems and mixed bed resins.

The difference is quite simple. We want to make this clear in the overview:

Mixed bed resins:

- Simple, chemical filtration process

- Water is passed through a granulate at line pressure

- The granulate binds all minerals and allows the H2O molecule to pass through

Advantages of mixed bed resins:

- Usually low acquisition costs (from € 350)

- Any water source can be used (including well water, although this is often very hard and causes correspondingly high running costs, see also disadvantages)

Disadvantages of mixed bed resins:

- High to extremely high running costs (€50-200 per 1000 liters)

- Therefore only suitable for occasional applications or soft water regions

- No pressure increase, therefore low height range (approx. 10 meters, depending on inlet pressure, tank size and water hardness)

- Generally low liter output per hour (80-200 liters, depending on inlet pressure, tank size and water hardness)

- Very poor ecological footprint (resin is disposed of or regenerated at great expense)

- The resin in the tank usually has to be disposed of after 3-6 months without use and can no longer be used

Osmosis systems:

- Mechanical filtration process

- Partly with different pre- and post-filters

- Sometimes (with high-pressure systems) also without post-filtration

- Water is separated into 2 parts by increasing the pressure in a membrane

- The result is a mineral-free part (permeate, pure water) and a mineral-containing wastewater (concentrate, extremely hard wastewater)

Advantages of osmosis systems:

- Virtually no running costs (often less than €1 per 1000 liters)

- Therefore suitable for regular work, hard water regions and large projects

- Large height ranges (up to 25 meters)

- High liter output (up to 800 liters per hour)

- Significantly better ecological footprint despite waste water (non-toxic and also not "gone")

Disadvantages of osmosis systems:

- higher acquisition costs (from approx. 3000 €)

- approx. 50% of the water flows away unused as concentrate

- only city water may be used (no well water)

- A power connection or power generator is required

- depending on the manufacturer and design, the machines must be switched on every 1-3 months, otherwise damage may occur

What else can I use osmosis water for cleaning?

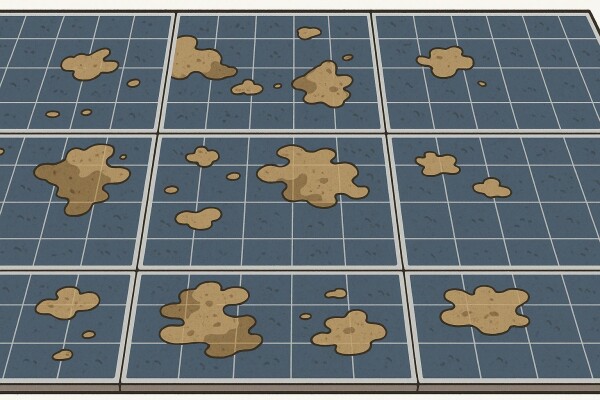

In addition to the cleaning of windows and glass surfaces described in detail, pure water is suitable for the chemical-free, fast and safe cleaning of all "dense and waterproof" surfaces. After glass cleaning, PV and solar cleaning should be mentioned here first and foremost. In contrast to glass surfaces, there is virtually no alternative cleaning method here, as it is not possible to work with textiles (as is the case with traditional glass cleaning to collect the chemicals) and it is virtually impossible to collect the cleaning chemicals and dirt in any other way. In addition, the osmosis water and the cleaning process are not primarily used for optical aspects. The aim is generally to increase the performance of the PV systems, which can be 5-20% after cleaning.

Pure water or osmosis water is also frequently used for the gentle and quality-assured cleaning of metal frames, advertising signs and for intermediate cleaning of vehicles.

Cleaning with pure water is less useful on mineral substrates such as plaster, clinker or painted wooden surfaces. The aforementioned pole systems can also be used here to avoid the need for ladders, scaffolding and cherry pickers. However, the actual effect of the clean water is lost here or is not necessary and not visible. Accordingly, tap water can often suffice here or cleaning chemicals may also have to be used.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian