Robots, rotating brush systems & lamella cleaners

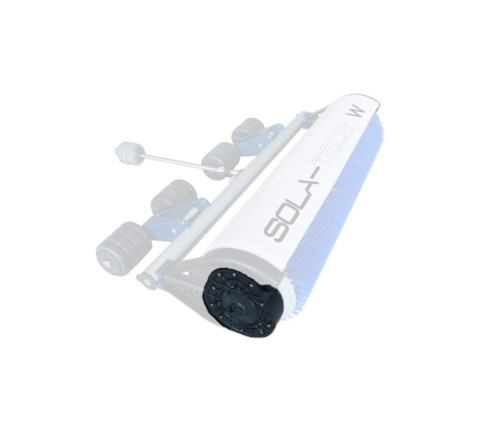

- Suitable for all SOLA-TECS W and W PRO models

- Spare part

- Spare part

- suitable for all SOLA-TECS C models

- quick and easy replacement

- Spare part

- Suitable for the QLEEN lamella cleaner

- quick and easy replacement

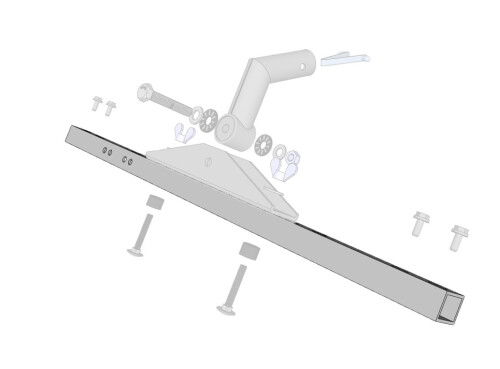

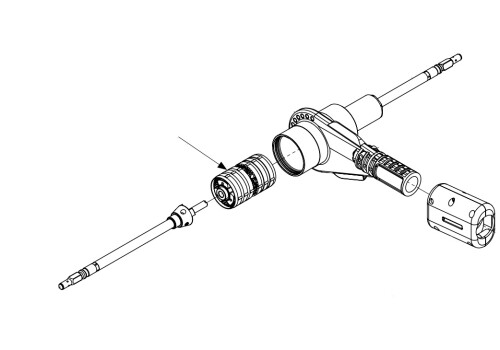

- Adapter

- Compatible with Unger nLite oval telescopic poles

- compatible with ROTAQLEEN

- easy handling

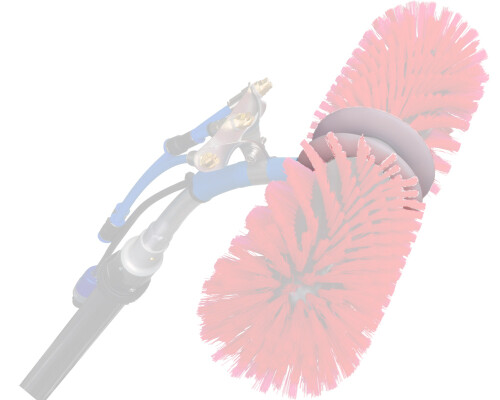

- Spare part

- Suitable for the ROTAQLEEN Vario

- quick and easy replacement

- Spare part

- Suitable for ROTAQLEEN Vario

- Quick and easy replacement

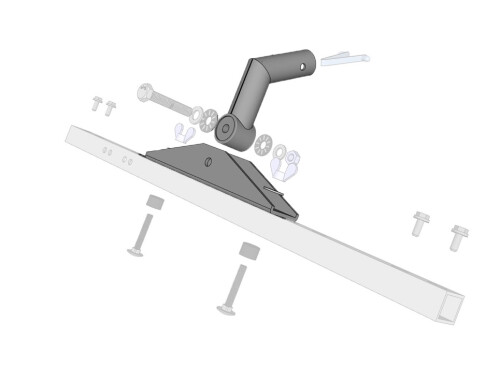

- For horizontal & simple control of the SOLA-TECS C

- Gives maneuverability

- Movable connection between brush & lance bow

- Adjustable to rotation ranges: 0°, 30°, 60°

- Spare part

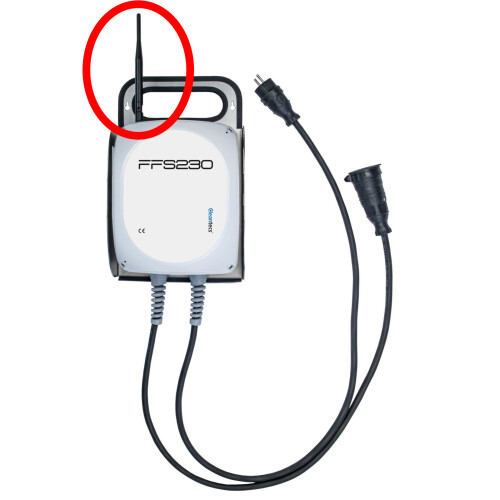

- suitable for SOLA-TECS radio control 230V

- Spare part

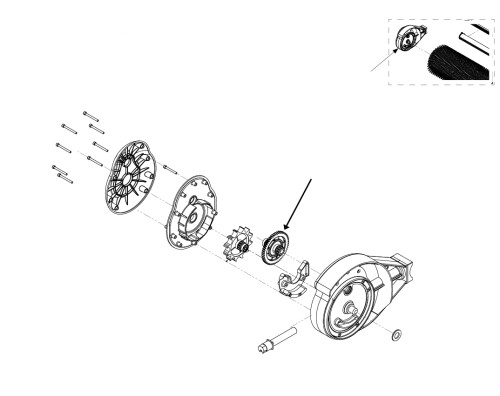

- suitable for SOLA-TECS W 800 mm and W 1000 mm

- incl. deep groove ball bearing

Here you will find rotating brush systems for solar cleaning and slat cleaning from market leaders Cleantecs, QLEEN and SPS-Cleaning-Systems. In close cooperation with the manufacturer, we exclusively offer the water-saving version of the SOLATECS C, among others. This can already manage with 300 liters of clean water per hour and delivers the full torque.BREAKRotating brush systems are used when the mere mechanics and the power of the clean water are no longer sufficient to achieve the desired result during cleaning work. The cleaning of very large areas or solar systems or slat systems can also be a reason to use a rotating system or a cleaning brush for slats. What is really innovative here is the operation of these water-pressure driven systems with pure water. This means that the surfaces to be cleaned do not even come into contact with the sometimes very hard and calcareous city water. Especially in summer, this water dries up very quickly anyway. In regions with water hardness of more than 20 degrees DH, subsequent cleaning can be more time-consuming than the actual cleaning to remove dirt and deposits. Accordingly, we recommend operating the systems directly with pure water that has previously been obtained using an osmosis system or a mixed bed resin. As 300 liters or more per hour are required here, even in the most economical version, the use of an osmosis system is generally the most economical, as there are no significant running costs. We will be happy to advise you in detail on which rotary washing system is best suited to your project and how you can operate it most cost-effectively with pure water.

Deutsch

Deutsch

French

French

Dutch

Dutch

Italian

Italian